Our Products

Caught in the waters of the British Isles and Norway, the crab are killed then cooked, broken apart and emptied, the outer shells – also known as the exoskeleton – are sent to C-Quest for processing. Caught in the waters of the British Isles and Norway, the crab are killed then cooked, broken apart and emptied, the outer shells – also known as the exoskeleton – are sent to C-Quest for processing.

The crab shells cleaning process involves scraping and removing all unwanted particles of meat that are still attached to the shell.

From the cartons containing the dirty shells, the first step consists of grading the shells.

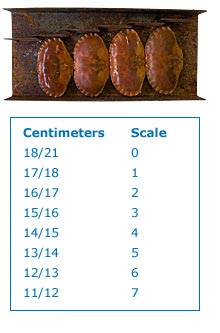

Grading

The shells are graded in a scale of 11cms to 21cms in width. After the shells have been graded they are put into plastic trays and soaked in containers of chemicals for 4 to 5 days. This soaking process helps to clean the shells from the residues of meat, or any other particles that are not suitable for human consumption. The trays are then removed and placed under running water. The shells are graded in a scale of 11cms to 21cms in width. After the shells have been graded they are put into plastic trays and soaked in containers of chemicals for 4 to 5 days. This soaking process helps to clean the shells from the residues of meat, or any other particles that are not suitable for human consumption. The trays are then removed and placed under running water.

The shells are then taken for a visual examination on their suitability for further processing, this takes into consideration any cracks, broken parts or chips.

Put onto the conveyor belt the perfect shells go through a thorough washing under pressured water, the shells are then counted and placed in plastic trays to drain.

After the cleaning process the trays are taken into the drying room and prepared for packing. One 5gm silica sachet is placed in each carton to keep shells moisture free. Any shells that do not fit the quality standards in size, cleanliness or natural look for the food industry are discarded.

Recommendation. It is advisable to sterilise the shells before using.

|